|

Learn

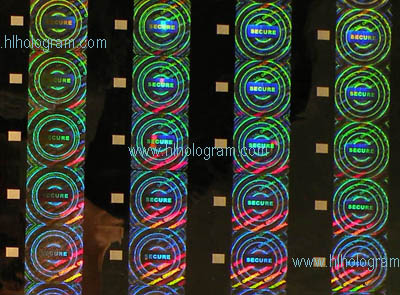

More About holographic label Holographic label samples 1

2 3

4 5

6 7

8 9

10 11

12 13

14 15

16 17

18 19

20 21

22 23

24 25

26 27

28

Holographic Universe Hologram knowledge1 Hologram knowledge2 Hologram knowledge3 Hologram basic Different Security Hologram Material Patterns Sequential Numbering, Ramdon numbering and Barcode onto hologram sticker Laser hidden text and Morie hidden text in hologram Hologram anti-counterfeiting technology

The principle of how hologram to play a security role on document, packaging, ticket, ....

First,

the hologram production and reproduction of technical content need for specialized personnel and complex process .

Hologram itself is a high-tech , it requires not only high-quality equipment shockproof station , lasers and various optical components and specialized chemicals , but more important is the need to operate technologically adept and experienced professionals , to produce qualified hologram master . Density of the hologram grating is usually 1000 lines mm undulation height of only a few tenths of microns , therefore requested to pay attention to the electroforming process and high - precision , high - quality molded copy device and holographic images Copy machinery . Manual with conventional equipment alone can produce the ordinary printing technology compared to the production of holographic trademark , technology , personnel , technology , equipment investment shows , making difficult not easily replicated performance .

Second, hologram its own structureis difficult to imitate even with with same working euipment and condition

Now most of the molded anti-counterfeit labels record one or more two-dimensional plane rainbow hologram pattern . Using hologram reproducing the characteristics of the three - dimensional stereoscopic image can be two (or more) planar pattern coding along vertical stratification recorded on the hologram , thereby re-emerged at different depths, each other plane image of the occlusion . Since the rainbow hologram has a variable nature of the color of the reproduced image , false color coding techniques can be used , so that different patterns or different portions in the same pattern reproduced in different colors . Hologram itself is a high - density complex grating, so even if the same person in different places with the same pattern and no legal system a grating identical two hologram , different people harder to copy . This difference is most obvious manifestation of for reproducing image layered depth and distribution of the different colors , of course , also includes the different indicators of the diffraction efficiency , the viewing angle , and SNR . So even with a full set of equipment and technology , generic the embossed hologram anti-counterfeit labels other home , is not an easy thing .

.jpg)

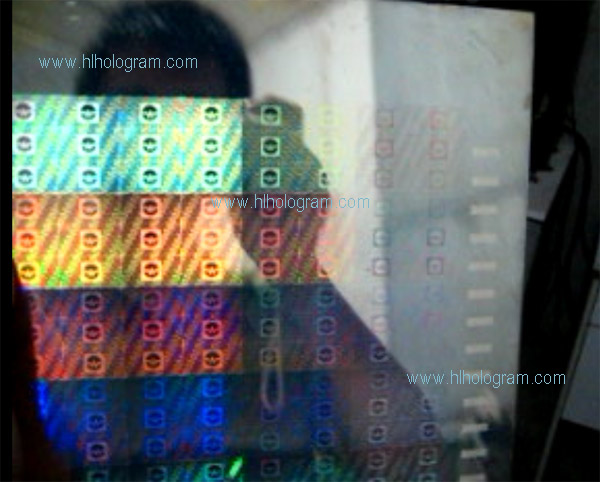

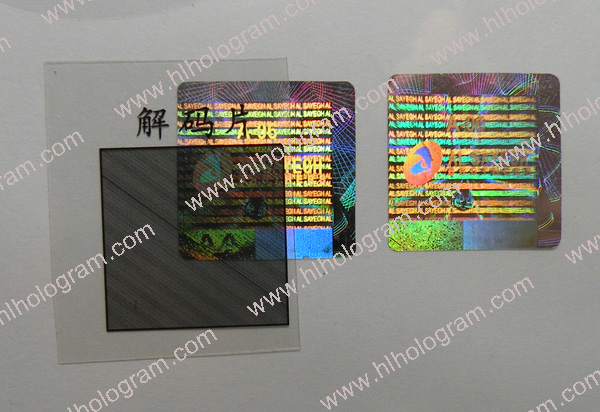

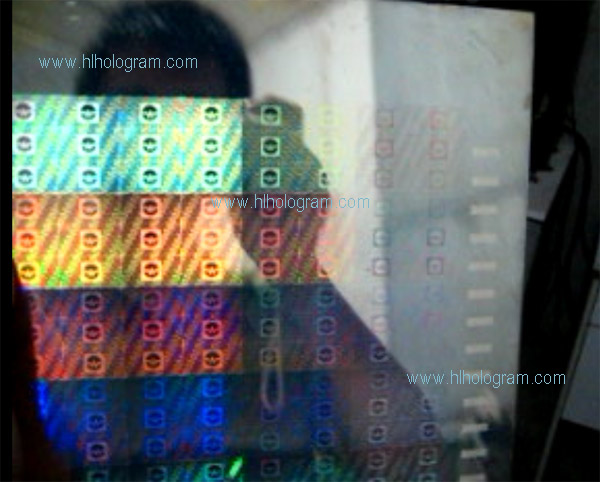

True Color holographic label and 2D holographic sticker with Honeycomb Tamper Evident. Honeycomb Pattern Release Tamper Evident

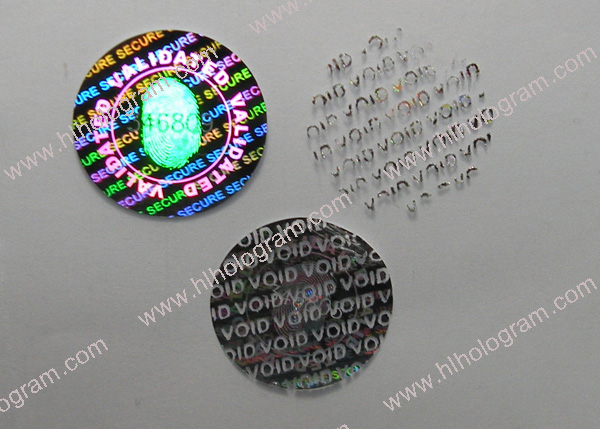

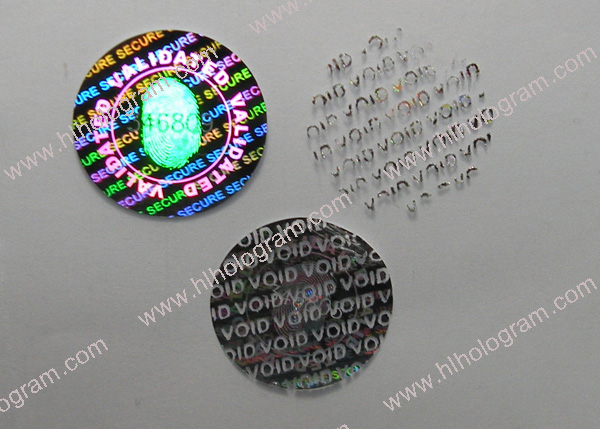

VOID Tamper proof of holographic label

VOID Tamper proof of holographic label. VOID Pattern Release Tamper Evident

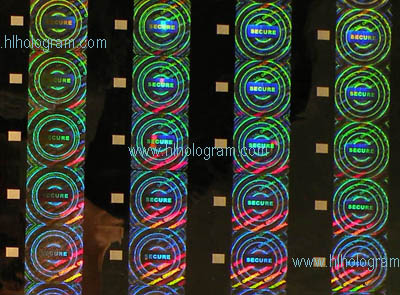

Security Numbering of holographic label. One is laser etching number, another is black ink number. Serial Number on Hologram Sticker

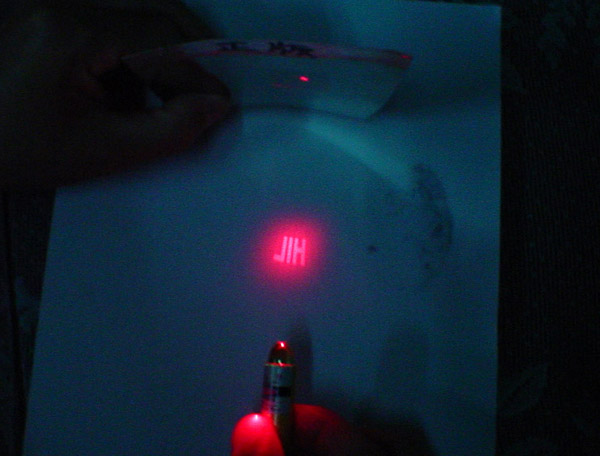

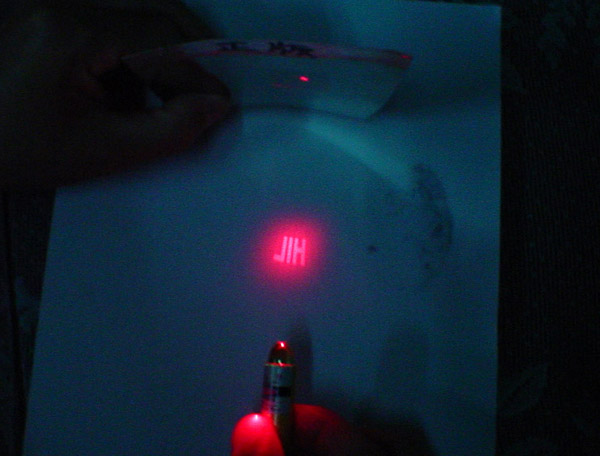

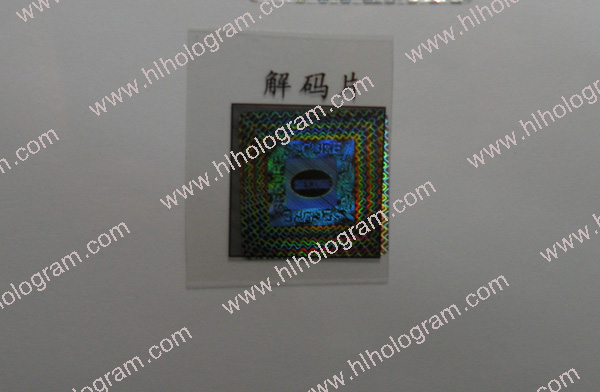

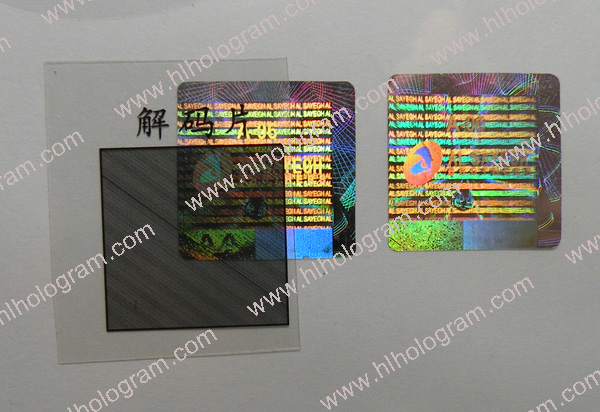

Third, encrypted information can be combined together with hologram. One is Laser Hidden Text(CLR images), another is Morie Hidden Text. UV Ink also can be printed onto holographic sticker.

The use of special optical coding technique can be encrypted, in the hologram These holograms or may be the reproduced size of the object with the human eyes to the change in distance between the hologram changes , or stored in the hologram of a point addition . information, or the hologram itself is generated by a computer , and so on . With a special three-dimensional object model as the target of the hologram , the reproduction is a perspective view identical to the original . Because of the higher technological content , and therefore more difficult to be generic .

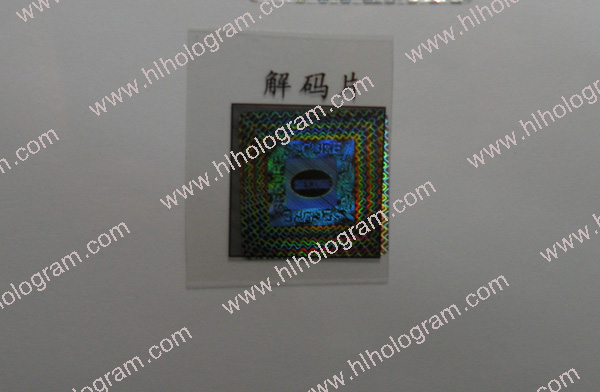

Laser hidden text is shown with laser pointer. Morie hidden information shown decode film.

Morie hidden information AA shown with decode film. Laser hidden Logo is shown with laser pointer.

Animated Hidden Image. Animation CLR image. It's a encrypted CLR flying bird which read by laser pointer.

Fourth, the anti-copy function material for hologram

Above us only from the point of view of the holographic process analysis hologram difficult to imitate . In real life , however , that such an approach , its use of embossed hologram peeled off to remove the aluminum layer of the film as a master , electroforming metal template , and then on the machine molded copy . Although so made ??of embossed hologram diffraction efficiency , and signal-to-noise ratio and other indicators of a decrease compared with the real thing , but the outcome is the hologram with enough means of anti - imitation , could not escape was easy imitation doom. To solve this problem , people developed the copy protection the tamper and stamping anodized aluminum film embossed hologram .

1 tamper Proof type

The tamper -type (also called disposable) embossed hologram the basic principle of the copy prevention : the lower surface of the resin layer and connected to the polyester material of the holographic plate plated by molding and deformed into a pressure-sensitive adhesive may be coated on the aluminum layer of the grating vector will the entire embossed hologram bear was pasted together . When the hologram is exposing the upper polyester film and the resin layer separation was peeled off , and will stick to the lower portion of the aluminum layer . Peeled off the polyester film is not grating , remain incomplete withstand the hologram on the matter has been damaged and therefore impossible for imitation .

.jpg)

VOID Tamper Proof. VOID Pattern Release Tamper Eviden

Normal Tamper Proof. Pressure Tamper Evident Holographic Sticker

Normal Tamper Proof. Pressure Tamper Evident Hologram Sticker

.jpg) .jpg)

Honey Comb Tamper Proof. Honeycomb Pattern Release Tamper Evident, ORIGINAL Pattern Tamper Evident,

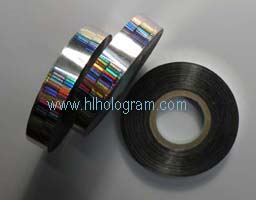

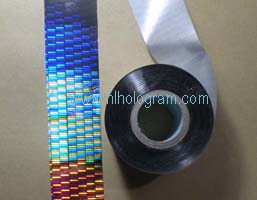

2, Hot Stamping

Stamping type hologram structure with the tamper -type hologram , that is the separation between the film and the resin layer of the former top polyester material in stamping when heat generated good separability , and coated on the bottom the thermosensitive gel when exposed to heat under pressure to produce a strong adhesive properties , and so with the aluminum layer and the resin layer of grating will closely adhered on the withstand matter , but simply could not be peeled off . Of course , from a philosophical perspective , the world does not exist and does not indestructible spear , shield there was no attack can not be broken , like all other things , there is always such a paradoxical relationship between anti-counterfeiting and forgery . To make holographic mark has to have a much higher security features than other printing production trademark holographic plate-making , printing processes , materials , and on the need to continue research and development of new technologies , the development of new products .

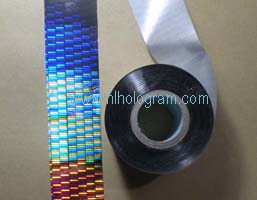

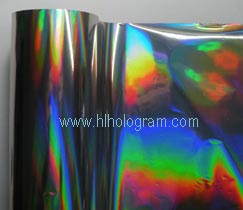

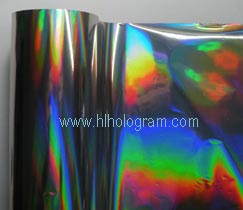

Hologram hot-stamping soil is a multi-layered PET film with hologram image. Generally, it starts with a 15-25 micron polyester carrier coated with a waxy release layer, then a special coating with the top coating layer to impart resistance to whatever hostile environment, the foil will be exposed to.

As the name suggests, the hologram foil is fused onto a host surface by means of heat and pressure. The host surface can be paper, plastic, etc., and once applied it becomes part of the surface and cannot be removed or transferred. This hologram coating protects everything beneath it. Beneath the top coating is the emboss able coating which receives the embossing of image. The material is then metallized by vacuum deposition of aluminum layer.

A single holographic image with a register or reading mark provided. Lots of customized design hologram hot stamping foils have registration marks which are traced by hot stamping machine automatic when application. The hologram logo will be transfer onto paper and PVC card by hot stamping process. The hologram fuses onto substrate and protects it.

Holographic hot stamping foil

Display Holography and Embossed Hologram Hologram Interferometry Measure

Holographic system stability

Since the hologram recorded on the interference fringe, and is a thin, dense, interference fringes, minimal interference will cause the blurring of interference fringes in the photographic process, and even the interference fringes can not be recorded. Example, shooting film displacement of a micron, the stripes on a confusion, the hologram experiment station is shockproof. Table hologram optics magnetic firmly sucked on countertops steel. Further, the airflow through the optical path, the acoustic interference, and temperature changes will cause changes in the density of the surrounding air.

Therefore, the exposure should prohibit loud noises, can not move around freely, the entire lab absolute quiet. Our experience is that each group tuned optical path, the students left the bench stable after a minute, and then came to light at the same time, to get a better effect.

Object light and reference light should meet.

Object light and reference light, an optical path difference should be as small as possible, preferably equal to the optical path of the two beams of light, up to not more than 2cm, adjusting the optical path with twine amount; the angle between the two-speed light at 30 ° ~ 60 °, preferably at about 45 °, because the angle is small, interference fringes on the thin, so that the lower the resolution requirements of the system stability and the photosensitive material; two light beams of the light intensity ratio should be appropriate, generally requires can be between 1:1 to 1:10, the light intensity ratio measured with a silicon photovoltaic cell out.

Using high-resolution hologram

Because recorded on the hologram backsheet is a thin, dense interference fringes, so the photosensitive material requires high-resolution. Ordinary photographic uses photosensitive film due to coarse particles of silver compounds can only record 50 to 100 per millimeter of stripes, the photosensitive film Tianjin plant the production of I-type hologram dry plate, with a resolution of up to 3000 per mm, can meet hologram photographic requirements.

Holographic photo of flushing process

The washing process is also critical. We follow the recipe requires dispensing with the developer, stop bath and fixer and bleach solution. The above several prescriptions are required to use distilled water, but the experiment proved successful with pure water preparation. The flushing process in the darkroom, the drug solution should never see the light and kept at room temperature about 20 ℃ rinse the preparation time drug solution custody properly, can be use in a month or so.

| ![]() English

English ![]() French

French ![]() German

German ![]() Spanish

Spanish ![]() Portuguese

Portuguese ![]() Italian

Italian ![]() Russian

Russian ![]() Romanian

Romanian ![]() Bulgarian

Bulgarian ![]() Hungarian

Hungarian ![]() Czech

Czech ![]() Danish

Danish ![]() Suomi

Suomi ![]() Turkish

Turkish![]() Swedish

Swedish![]() Norwegian

Norwegian![]() Slovenian

Slovenian ![]() Polish

Polish![]() Croatian

Croatian ![]() Slovak

Slovak ![]() Maltese

Maltese ![]() Lithuanian

Lithuanian![]() Latvian

Latvian![]() Slovak

Slovak ![]() Afrikaans

Afrikaans ![]() Arabic

Arabic ![]() Chinese(S)

Chinese(S) ![]() Chinese(T)

Chinese(T) ![]() Japanese

Japanese ![]() Korean

Korean ![]() Vietnamese

Vietnamese ![]() Thai

Thai ![]() Malay

Malay ![]() Indonesian

Indonesian

.jpg)

.jpg)

.jpg)

.jpg)

07000688

07000688